Aker Solutions Set to Deliver Modules for World's First Subsea Compression System

December 12, 2014

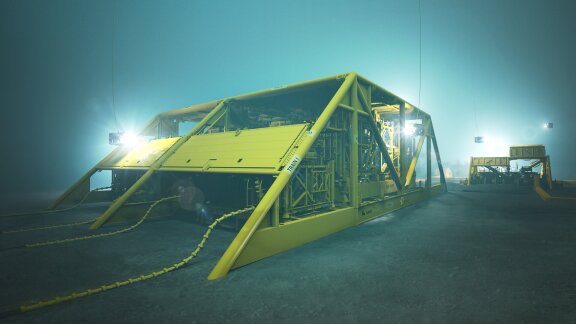

The modules will be assembled into two trains that will each hold a compressor. They will be placed in an 1,800-tonne steel frame that was installed at the Norwegian Sea field in July last year. The modules for the first train will be delivered in instalments from now through January. The second train and compressors will be delivered in the first quarter of next year.

The compression system will boost gas pressures at the Midgard and Mikkel satellite deposits in the Norwegian Sea to potentially extend Åsgard's production life by as many as 20 years.

"The groundbreaking technology at Åsgard brings us one crucial step closer to placing a fully-functioning production and processing system on the seafloor," said Per Harald Kongelf, head of Aker Solutions in Norway. "This will be a game-changer for the industry that makes it possible to increase recovery and lower costs at subsea fields."

Extending Field Life

Gas compressors are used to keep up output as reservoir pressure at gas-producing fields drops over time. While such compressors have typically been installed on platforms over sea level, placing them on the seabed and near the wellheads improves recovery rates and reduces capital and operating costs. Subsea compression also leaves a smaller environmental footprint and is safer to operate than a platform.

The Åsgard subsea gas compression facility is set to go on stream in 2015 after the two 11.5-megawatt compressors are installed. The project is operated by Statoil and delivered by Aker Solutions.

ENDS

Aker Solutions is a global provider of products, systems and services to the oil and gas industry. Its engineering, design and technology bring discoveries into production and maximize recovery. The company employs approximately 17,000 people in about 20 countries. Go to www.akersolutions.com for more information on our business, people and values.