Offshore Wind

What can Aker Solutions provide to offshore wind developers?

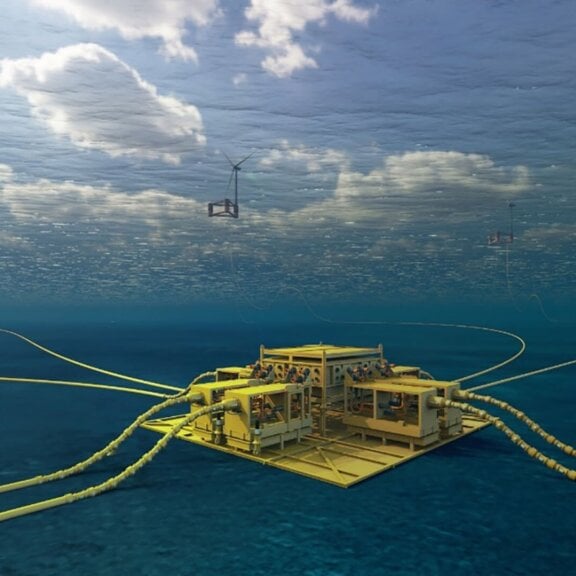

- Offshore substations | We deliver HVDC, as well as floating, bottom-fixed, and subsea HVAC substations. Our engineering experts and construction yards can collaborate with any HV equipment supplier (OEM).

- Gravity-based structures | Concrete GBS offer long lifetime, low maintenance, sustainable alternatives with local production potential. Gentle seabed installation has low impact on local wildlife.

- Steel jacket substructures | Steel is a cost-competitive alternative when serially produced on our fully automated production line. We deliver complex steel jacket structures for substations, offshore platforms, and turbine foundations. Our services include early phase studies, FEED, EPC, to lifetime extension and demobilization.

- Floating foundations | Aker Solutions has three tested and project-ready foundations for floating wind, and an unmatched track record for the successful design, delivery and project execution of offshore floating facilities in concrete or steel.

- Marine operations | Load-out, sea-fastening, transportation, and installation of the foundations and topsides are handled by our highly experienced marine operations unit, augmented by the Windstaller Alliance.

Products

Offshore structures & solutions

For 50 years, we've had a leading position in design and construction for offshore oil and gas and we are evolving our expertise to support the renewable energy segment.

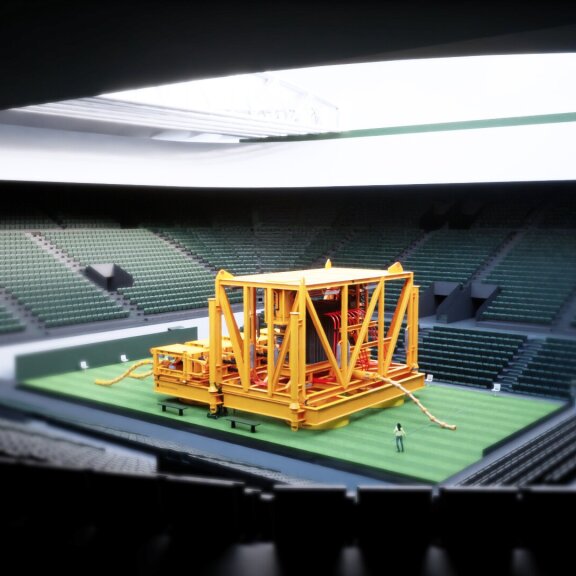

Aker Solutions sets the benchmark for offshore engineering and project execution. Our team of experts has used their experience in engineering, procurement, fabrication and installation, to design and develop state-of-the-art floating wind substructures, substations and power collectors.

Our solutions are designed to provide stable and efficient conditions for wind turbines, to provide highest possible degree of energy production.

We combine a unique international offshore track record with proven competence across the entire offshore wind value chain.

Track record in offshore wind

Our product portfolio spans from subsea systems to floating foundations.

- USA | Sunrise Wind (924 MW) | HVDC substation

- UK | East Anglia THREE (1320 MW) | HVDC substation

- UK | Norfolk Vanguard West (1320 MW) | HVDC substation

- UK | Norfolk Vanguard East (1320 MW) | HVDC substation

- Norway | Hywind Tampen (88 MW) | 11 floating foundations for wind turbine generators

- Aker Solutions launches 3 new floating foundations for offshore wind

Services

Realising offshore floating wind

Our solutions are designed to provide stable, secure and efficient conditions for wind turbines to enable maximum energy production.

From concept to completion, we manage every aspect of floating wind projects. Our integrated approach ensures seamless execution, on-time delivery, and follows the highest safety and quality standards. Read more about our commitment to safeguard people and assets. We believe all incidents can and should be prevented.

Related news

Want to know more?

Let’s connect! One of our experts will get back to you as soon as possible, normally within 24 hours.

Floating Offshore Wind

Business DevelopmentNorway Local time: 00:09 CET